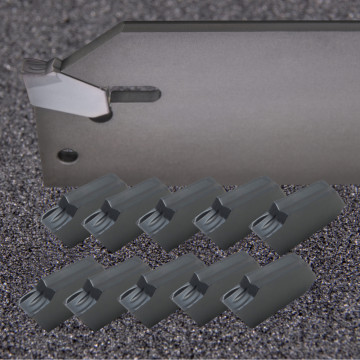

Set 1x MK45 SNEG12 + 10/20x SNEG Milling Inserts

Set consisting of:

1x MK45 SNEG12

10/20x Milling Inserts SNEG

Face Mill-Set of your Choice:

| D | d | L | ap max | Z | |

| MK45 SNEG12 D050 A22 Z05-H + 10 Inserts | 50 | 22 | 40 | 7 | 5 |

| MK45 SNEG12 D063 A22 Z06-H + 10 Inserts | 63 | 22 | 40 | 7 | 6 |

| MK45 SNEG12 D080 A27 Z07-H + 10 Inserts | 80 | 27 | 50 | 7 | 7 |

| MK45 SNEG12 D100 A32 Z09-H + 10 Inserts | 100 | 32 | 50 | 7 | 9 |

| MK45 SNEG12 D125 B40 Z11 + 20 Inserts | 125 | 40 | 63 | 7 | 11 |

Mill Inserts of your Choice:

| L | I.C | S | d | r | Scope of application | |

| SNEG 1205-GM RT305 | 7,6 | 12 | 4,76 | 4,6 | 0,8 | Steel/Stainless Steel/ Specials Materials |

RT305 = PVD grade M20-M30 for stainless steel with the most modern coating

Packaging unit= 1 Pc.