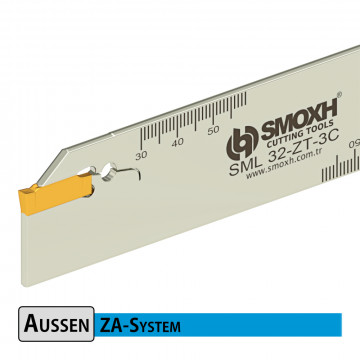

External Grooving Holder - BDKTR/L - MGMN t max:40

| Grooving Holder | BDKTR/L t max:40 |

| Application | Outside Grooving |

| Grooving System | MGM./MRM.-System |

| Grooving Insert | MGMN/MGMR/MRMN... |

| Packaging Unit | 1 Pc. |

| h=H | B | L | f | t max | d max | |

| BDKTR 2525-K3C t max:40 for MG../MR 300 (3mm) |

25 | 25 | 170 | 25,4 | 40 | 84 |

| BDKTL 2525-K3C t max:40 for MG../MR 300 (3mm) |

25 | 25 | 170 | 25,4 | 40 | 84 |

| BDKTR 2525-K4C t max:40 for MG../MR 400 (4mm) |

25 | 25 | 170 | 25,4 | 40 | 84 |

| BDKTL 2525-K4C t max:40 for MG../MR 400 (4mm) |

25 | 25 | 170 | 25,4 | 40 | 84 |